Want a professional finish for a project? That usually means you have to get a great looking and functional enclosure for it… 3D printing can be the solution here. Or you need a weird, oddly specific bracket to hold something in place? Again, you could turn to 3D printing for that.

While other projects are still brewing, I wanted to highlight a five cases where 3D printing has helped out projects of mine tremendously. If you are looking for tips how to print, look at the post on 3D printing settings!

1. Cases for Electronics

Electronics projects often start with a handful of printed circuit boards (PCB) that are soldered together have some LEDs, buttons or switches attached to them. Not only does this look bad, it is hard to move and when inevitably dust start to pile up on the PCB it is hard to clean with all the components. Having a proper case for your project makes all the difference. While generic cases are available, these never fit quite right and still require a fair bit of work to house you project … for which I lack the tools and skill … So having access to a 3D printer has been a boon. The Zigbee stick I purchased to connect Zigbee devices to Home Assistant (check this post) is a great example how a bare PCB can be turned into a good looking device with a simple print.

Though I have also printed enclosures for a Raspberry Pi with mounting holes to install it inside a technical space next to the router. A 3D printed case here costs a few dollar for 100-200 grams of filament and you can pick one that fits to your needs exactly. I mostly needed something which could be wall mounted easily, though you might want something that fits a specific HAT, switches, … either there will be someone that designed it already or you can modify an existing design.

2. Designer Storage

Need custom storage? 3D printing can be a boon! For my dice (which are used as counters for Magic The Gathering) and tokens (KeyForge) I started with an existing design, added a pattern I liked and reworked the case into something that fits my use case exactly. How these were printed and finished is shown in my post on 3D printing settings.

3. Niche Parts

Not long before this blog started, I’ve built a GameBoy Zero, which requires retrofitting a new PCB, a Raspberry Pi Zero and a few other components in a GameBoy shell. To keep those items in place a number of 3D printed brackets can be printed. There actually is a whole community building these over at SudoMod where people share their designs (and printed parts for those without access to a printer) so even for such a niche project you don’t need to do any 3D Modeling yourself. I actually still have enough parts for a second build … so I guess there will be a post here detailing the process once I get around building it.

4. Extremely Specific Stuff

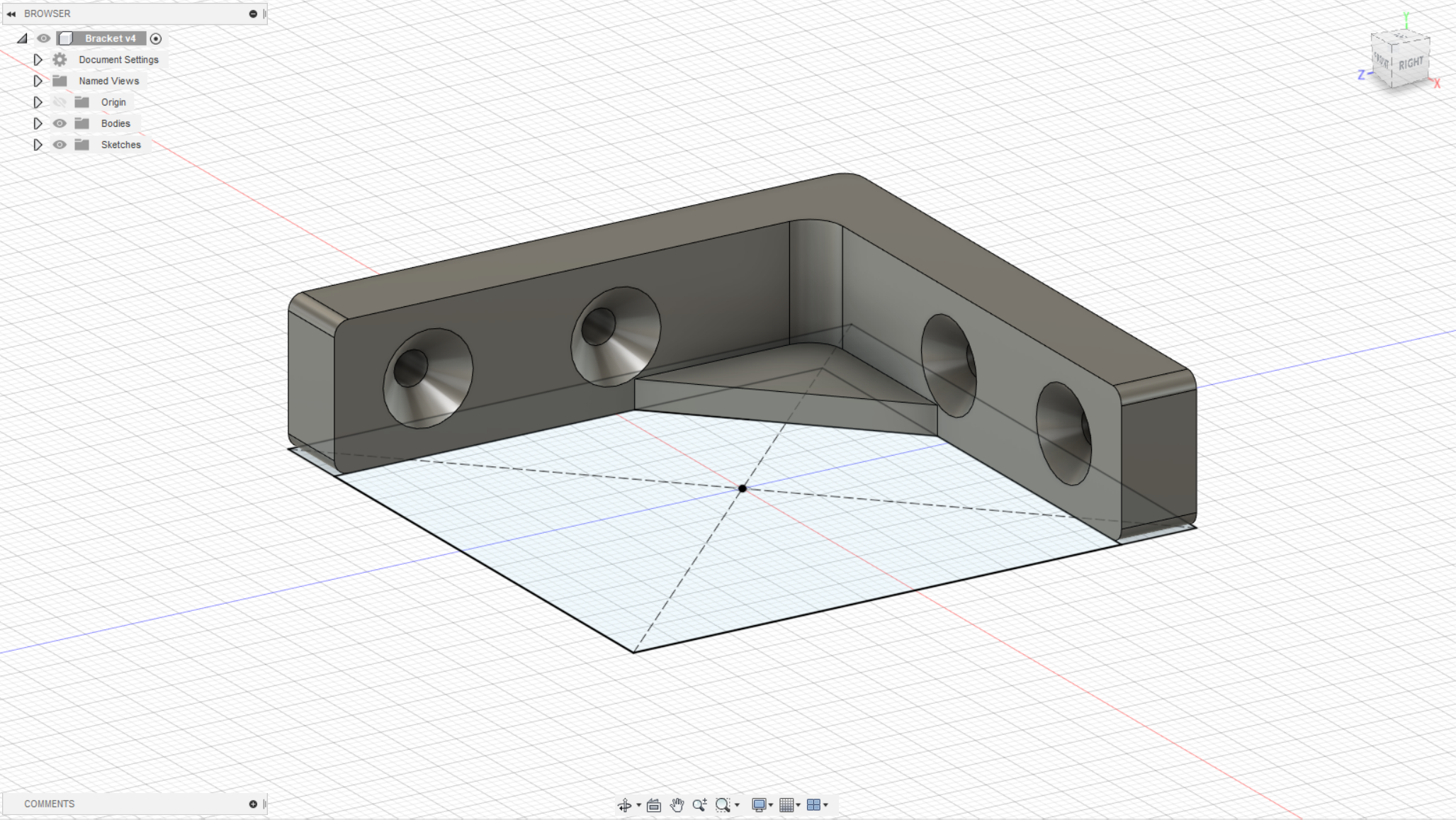

During summer we have built some garden furniture out of old pallets, and some were a little wobbly. The reclaimed wood from pallets isn’t perfectly straight and the glued joints weren’t always perfect. So a few L-Brackets needed to be added to make sure everything stayed stable! Since the hardware store was all out, I designed them in Fusion360 and printed a bunch. This way I could also add the perfect countersink for the screws and extra support.

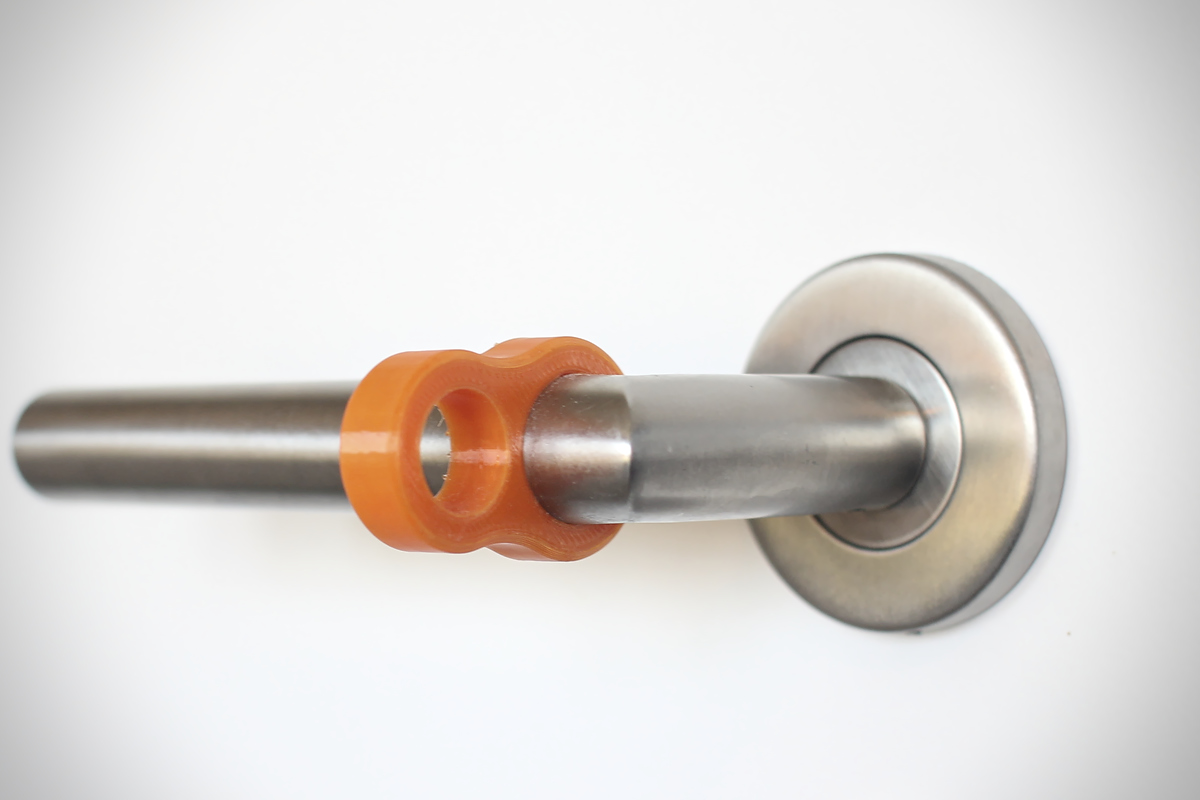

Another case where 3D printing helped out was to add a soft bumper to a cylindrical door handle. This door could potentially slam into the closet. Normally not much of an issue, as you can put something to block the door on the ground, … except every off-the-shelf solution would also block that closet from opening. The other option which I have seen in other people’s houses it so cut up a pool noodle and put that over the door handle … which I would consider for the basement storage, but not for other rooms. So after finding a design for a little bumper that can be printed in a soft material like TPU I fired up Fusion360 and replicated the design to match our door handles exactly.

5. Faster than Ordering Online

Some things you can easily find online. Though why wait a couple days for it to arrive if you can print a solution today?

My kindle-turned-into-dashboard from the previous post is a good example. It needed a stand, preferably one with enough clearance at the bottom so that an (angled) USB cable could still be connected to keep it plugged in. There are plenty of stands for cell phones, tablets, … to be found that would fit this description. But I wanted to try and design something myself that fit the requirements. And came up with this :

This is perfect for the kindle and generic enough that it can be used for other items. It prints without supports and when printed flat maximises the strength.

If you like to print this yourself, you can do so using the STL files below!

Liked this post ? You can buy me a coffee